Project Summary

Beneficiary Organization approached Engineering Good (EG), requesting an affordable hotplate that is custom designed for the visually impaired in mind.

https://enablingvillage.sg/2018/04/19/6-tools-that-belong-in-every-blind-persons-kitchen/

There is already a commercial product available in the market, however it is a bit pricey and rather old – it possesses several design flaws many parties feel should be rectified.

EG accepted this project with the intention that any and all modifications made are cheap and open-source (as follows EG’s core principle), so that any and all makerspaces are able to replicate EG’s creation for the benefit of others.

For the sake of ease and cost, EG has decided to procure an affordable hotplate and will modify it to include whatever requested features that are not already present.

This stove reads its settings out loud as you set the temperature. It has safety features such as turning off after a preset period, and a magnetized base for stainless steel pans and pots. The hob also turns off immediately when a pan is removed.

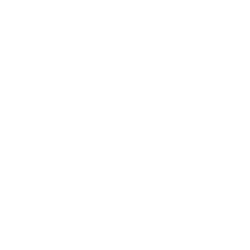

Product to be Modified

by Engineering Good

Mistral Induction Cooker – MIC2110

The item was purchased from FairPrice Xtra @ NEX for $65.

Requested features:

Tactile aids for the visually impaired (e.g. identifying buttons, locating the ‘cooking surface’)

Able to ‘speak’ its current settings

Light(s) indicating whether the ‘cooking surface’ is ‘too hot’

(Bonus) Integrated timer

(Bonus) Integrated weighing scale

Project Team :

Saad

Damien

Lynette

Shawn

Entry #1:

Stripped the hotplate and found that the innerworkings are modular, making the hotplate’s control panel easy to separate from the main induction heating machinery.

Saad mentioned that for the ‘speaking’ function of the hotplate, it’ll be very easy to modify the existing control board and take advantage of its attached Integrated Circuit (IC) chip. I personally have no clue how to pull that off but we’ll cross that bridge when we get there.

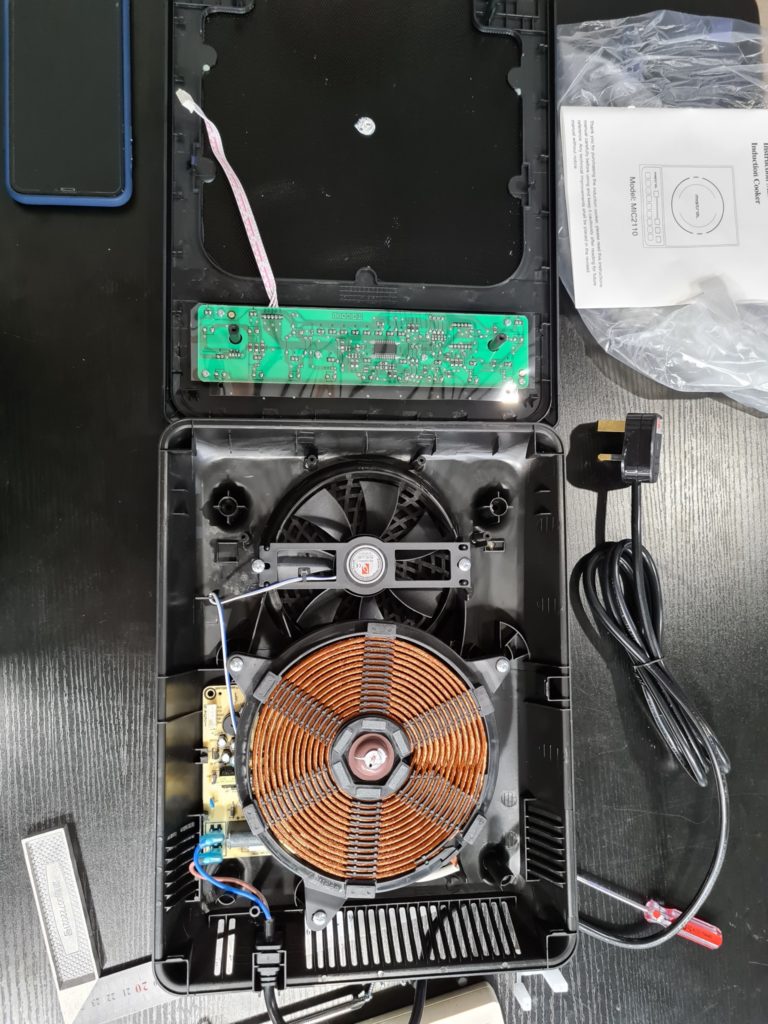

Saad also came up with a quick sketch on how we can pull off the remaining modifications (a clearer and more detailed version will be posted soon (hopefully (I think)))

Entry #2

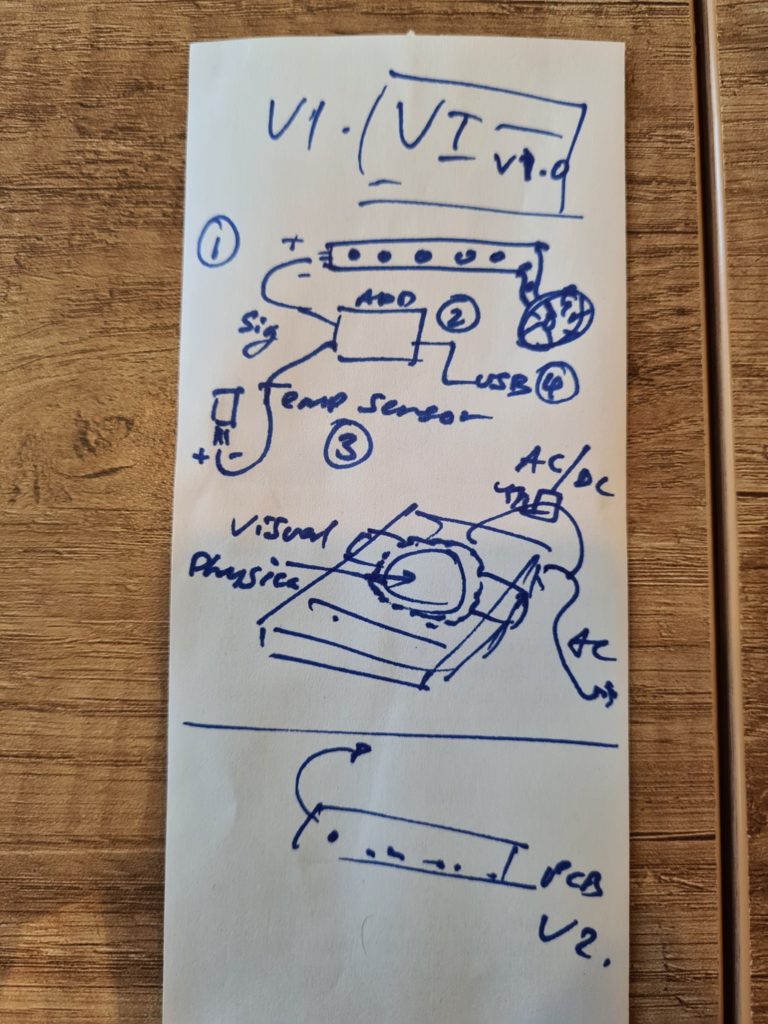

Today, we worked on the application of an LED strip and external digital temperature sensor, both controlled by the Ardunio Nano (turned out that my computer was the problem), for the hotplate.

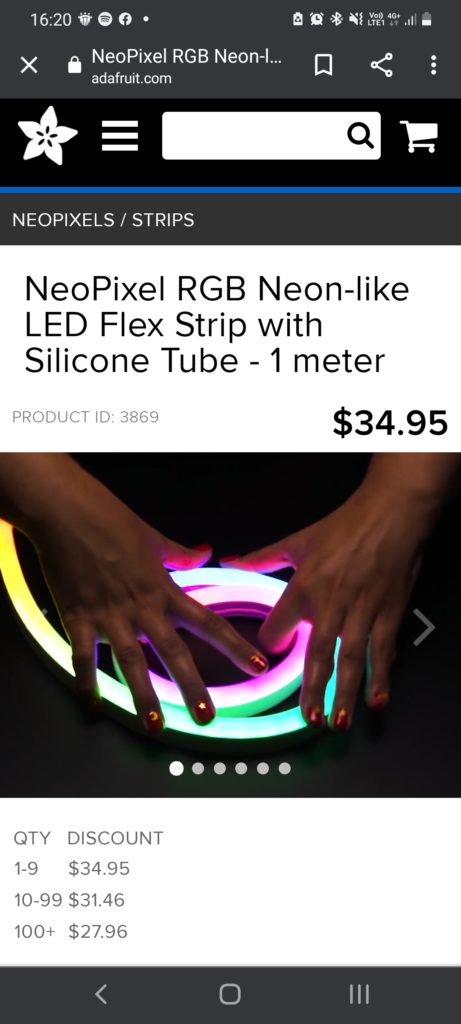

For the LED strip, Saad got a NeoPixel LED strip; for the temperature sensor we used a digital sensor (forgot the exact model name) from an all-in-one kit that Saad had.

The sensor has a small bronze screw that controls the sensor’s temperature ‘threshold’ (not the range of temperature it measures), so we had to crank it to the perfect point where at room temperature it was ‘off’ and once we put it between our fingers it was ‘on’ (due to body heat). We took the code from the manufacturer’s website and modified it slightly to better suit our purpose, the code is all in the Macbook Pro Saad lent us.

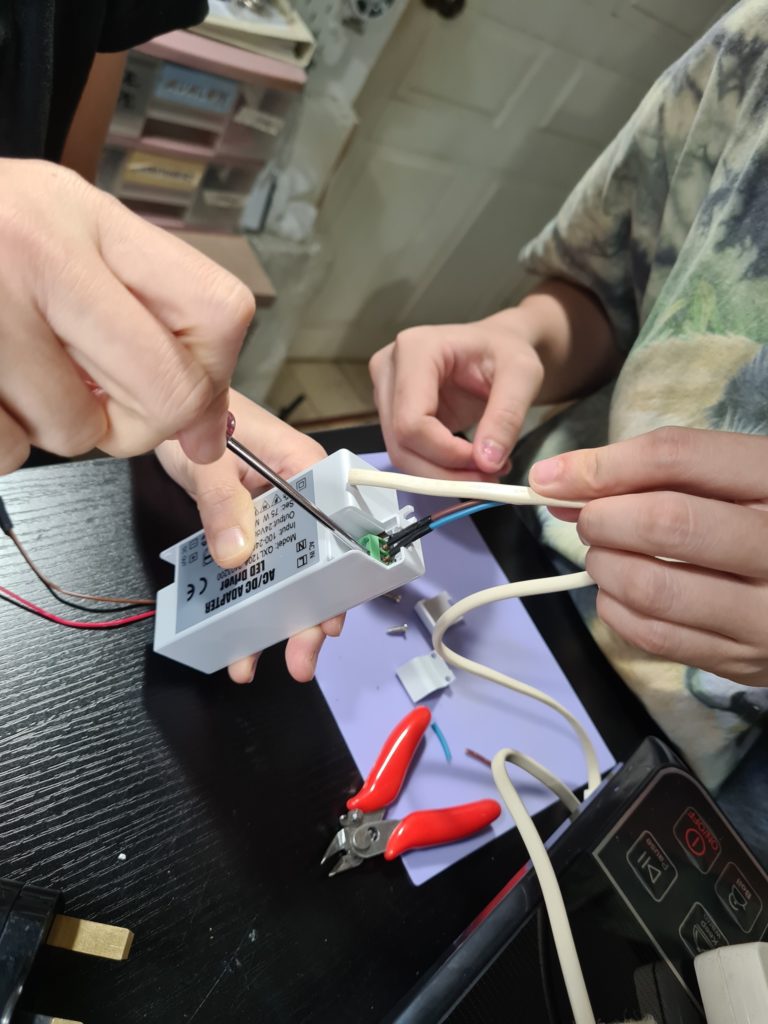

For the LED strip, it requires a 24V power source which the Arduino Nano cannot provide (5V), so we had to create a small AC/DC power supply. This was done by cutting off the tail head of a wall plug, taking its wires and hooking it into a small 24V AC/DC transformer, and then hooking that to the ground and power supply wires of the LED strip – the signal wire is connected to the Arduino Nano.

Something to take note of is that the ground must also be hooked up to the Arduino Nano (so the LED strip has a 3-way connection), otherwise the signal the LED strip received will be ‘glitchy’.

The code for the LED strip’s code still needs to be worked on. Copying it straight from online doesn’t work perfectly, and apparently we need to take note of the exact NeoPixel product we’re coding for for it to work properly. Saad knows more about this, so we’ll continue working on this next time!